This article will explain how to use SparkKing CDI System , to replace the original CDI system

on a Suzuki AN125 motorcycle.

The followed are the basic specifications about Suzuki AN-125

Displacement: 124 cc

Engine type: Single cylinder (single overhead cam – SOHC), 4 stroke, air cooled, automatic

Bore and stroke: 52mm x 58.6mm

Lubrication: Wet sump

Oil filter: Filtrex OIF011, Hiflo HF131, Champion X327

Clutch: Variator type clutch

Gearbox: Automatic

Gearbox oil: From engine (doesn’t need a separate gearbox oil)

Power: 10.2 bhp (UK model)

Torque: 10 nm

0-60 mph time: 15.9 seconds

Electric stuff

Ignition type: Electric CDI

Starter: Electric start and kick start

Electrical system voltage: 12 volts

Spark plug (AN125 S – Feb 1995 to Dec 1995): NGK CR8E

Spark plug (AN125 T/V/W – Jan 1996 to Oct 1998): NGK CR7E

Spark plug (AN125 X – Nov 1998 to Nov 2000): NGK CR8E

Battery: AN125 battery – YTX7A-BS / CTX7A-BS

Starter: Electric start and kick start

Electrical system voltage: 12 volts

Spark plug (AN125 S – Feb 1995 to Dec 1995): NGK CR8E

Spark plug (AN125 T/V/W – Jan 1996 to Oct 1998): NGK CR7E

Spark plug (AN125 X – Nov 1998 to Nov 2000): NGK CR8E

Battery: AN125 battery – YTX7A-BS / CTX7A-BS

----------------------

Step 1: Remove the Front cover

---------------------------

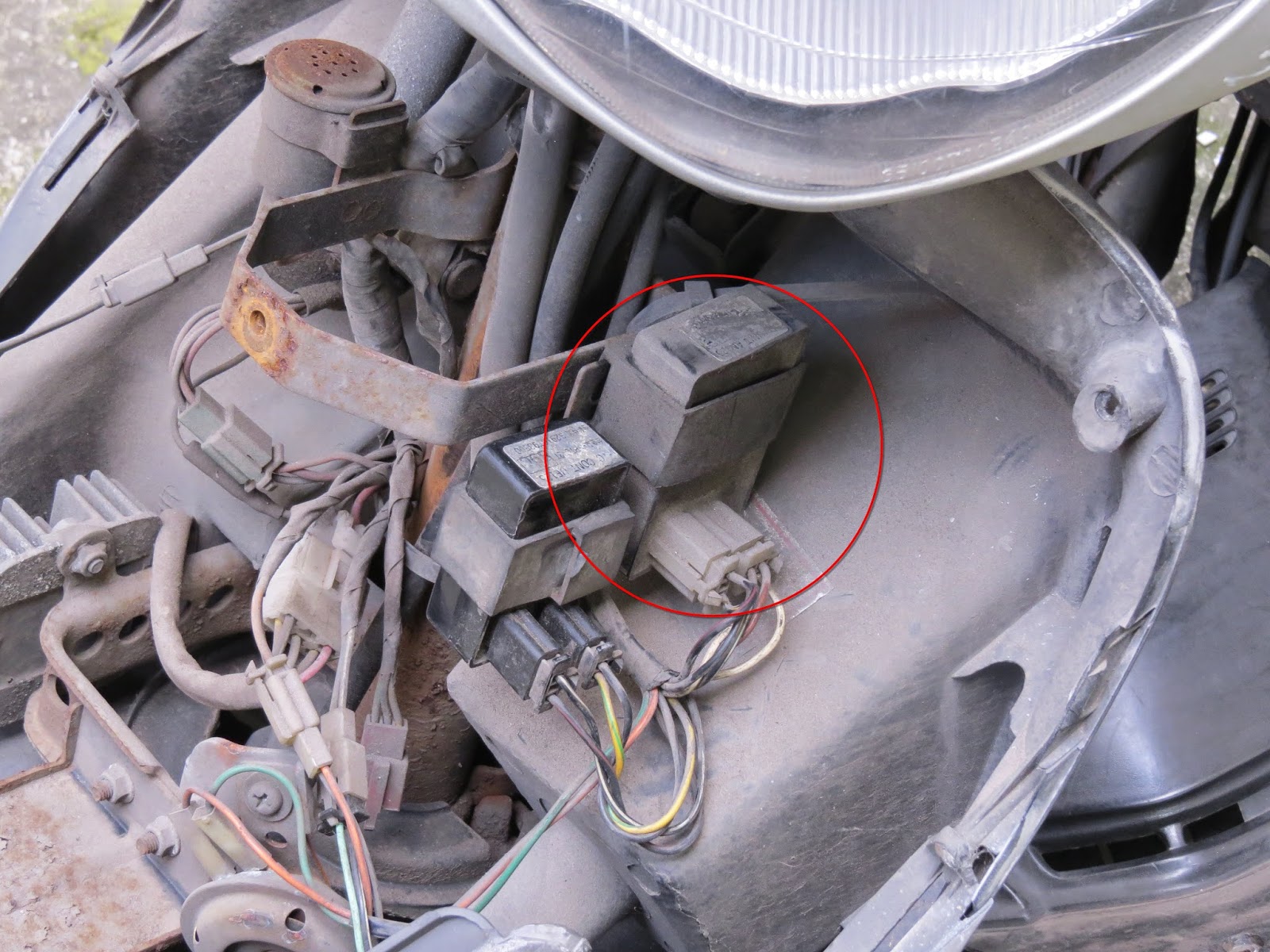

Step 2: Find out the location of original CDI

The connector are 2 wire(B/R and B/Y) + 4 wire (Br, W, B/W and W/Bl).

----------------------

Step 3 : search the wiring diagram from Google :

we know the original CDI is AC-CDI.

The wire B/R is the AC power source of CDI from magneto. this wire we don't need

for ours SparkKing CDI (DC-CDI) .

The wire B/Y is the turn-off switch of AC-CDI. we don't need, too.

The Br and W are the pick-up signal from magneto. where W is wired to ground.

--- you can find out the W is wired to ground using multimeter.

The B/W is wired to Ground, ie the negative of Battery.

The W/Bl is wired to the ignition coil.

--------------

Step 4 : Make a Y-Wire in order to measure the ignition timing on original CDI.

We need the pick-up and ignition coil signal to connect to ours SparkLink+.

The Y-wire is to intercept the pick-up signal easily.

|

| Make a wire to acquire the ignition timing. |

The Box is the SparkLink+ Tool.

Now you can execute the SparkKing App Software on the PC. and start the engine ...

-----

We can acquire the main ignition timing on the original CDI easily.

---------

Step 5 : Replace the Original CDI Using the SparkKing CDI System.

Make a customize wire to match the original connector. where Y wire is the DC-Power from the positive of Battery. You can wire to any switched power line on vehicle.

--------------------

Step 6 : Now you can change the ignition timing chart of SparkKing CDI to match the original CDI Ignition timing.

----

Step 7 : Start the engine... and success !!

We can acquire the main ignition timing on the original CDI easily.

---------

Step 5 : Replace the Original CDI Using the SparkKing CDI System.

Make a customize wire to match the original connector. where Y wire is the DC-Power from the positive of Battery. You can wire to any switched power line on vehicle.

--------------------

Step 6 : Now you can change the ignition timing chart of SparkKing CDI to match the original CDI Ignition timing.

----

Step 7 : Start the engine... and success !!

----

We have also GY-6 Engine did same thing on.

We have also GY-6 Engine did same thing on.

---

DC-CDI advantage is that you can get more stable power supply from Battery. Relatively easy to start-up engine, and stable on the idle speed of engine.

Similarly, in the entire engine speed range, can also be obtained relatively more stable power supply.

And we can also understand :In the conversion process, the magneto specifications will not affect the DC-CDI installation.

----

Key

Features

DC-CDI advantage is that you can get more stable power supply from Battery. Relatively easy to start-up engine, and stable on the idle speed of engine.

Similarly, in the entire engine speed range, can also be obtained relatively more stable power supply.

And we can also understand :In the conversion process, the magneto specifications will not affect the DC-CDI installation.

----

SparkKing – Programmable and Powerful CDI solution

Overview

The SparkKing CDI(Capacitor Discharge Ignition) provides a

high-performance, programmable motorcycle engine ignition system. SparKing allows

you to quickly set the spark advance angle based on the specific RPM. By the repeated modify and tuning the spark

advance angle, SparkKing may being suitable easily in any small (motorcycle) engine’s

ignition system. Ultimately, it will speed up users’ tuning the spark timing process

for any modified engine dramatically in a much efficient manner.

SparkKing

uses a high-performance, high-integration Micro-controller which provides a

fast and stable operation and signal processing facility. And, the SparkLink

toolkits cable which leveraging USB connection and plug-and-play driver, a naive

user can easily check and diagnose the spark advance angle table in the

SparkKing CDI. This allows engine engineers to focus on tuning and diagnostic their

ignition system. At the same time, SparkKing may also enhance the productive

efficiency of CDI, reduces the product inventory risk.

Key

Features

◆

Protection

circuit for power source.

◆

Embedded

DC-DC Converter circuit, Support DC Type CDI (Capacitor Discharge ignition)

system.

◆

Checking

and Diagnostics Interface.

◆

Programmable

spark advance angle table.

◆

Flexible

Engine Reference signal configuration.

◆

Up to

15600 rpm supported.

◆

Maximum

60 degree spark advance angle supported

◆

Enhance

One Shot Engine kick-start procedure

◆

Compatible

for traditional DC-CDI function.

Basic Specifications

◆

Name : DIGITAL DC-CDI.

◆

Functions :

* SCR switching type.

* Capacitor charging type : DC converter type

* Discharging Mode : AC-ARC

* Ignition control : Map change control by

RPM

* Regulated voltage 25V MAX.

◆

Applicable

Revolution : 230 ~ 15600 rpm

◆

Operation

Temperature : -10~+60゚C

◆

Storage

Temperature : -20~+80゚C

◆

Power

source : 13.0V

◆

Condenser

Capacity(For Ignition) : 1.5μF

◆

Compatible

for traditional DC-CDI function.

The connection diagram is shown as followed :

是否可將 DC-CDI 的電源線接回鑰匙處,讓鑰匙可以開關 DC-DCI。

回覆刪除Yes! This is connected the Power as you said in step 5. The y-wire get the power from main switched key already

刪除全伯先生:

回覆刪除请问这个界面是用什么做出来的,好漂亮呀!

谢谢!